QUFU JINHUANG PISTON CO.,LTD

Zip code: 273100

Address: Qufu Economic Development Zone, Golden Road on the 1st

Ministry of Foreign Trade Tel: 0537-4719627

Sales email: andy@jhpiston.com

Website: http://www.k990.cc

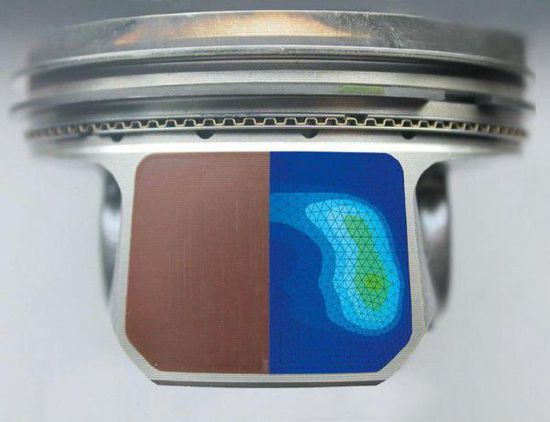

According to foreign media reports, the piston skirt and piston pin combustion engine is the most difficult to maintain the state of lubrication and have the largest contact surface in the parts, the entire engine friction loss, they share up to about 17%. Recently, OE powertrain manufacturer Federal-Mogul announced two new engine coatings that reduce friction by up to 15% compared to standard engine coatings.

In the past, engineers had achieved the goal of reducing frictional losses on piston skirts and piston pins by optimizing piston clearance, and now they are starting to take advantage of advanced coatings on cylinder walls and piston groups. This means a huge improvement in engine life, fuel economy and kinetic energy output. Federal-Mogul Powertrains said their recent EcoTouch coatings for petrol and diesel engines allow them to go further with the goal of reducing friction loss, where diesel engine piston skirts wear at up to 40% less than market standards.

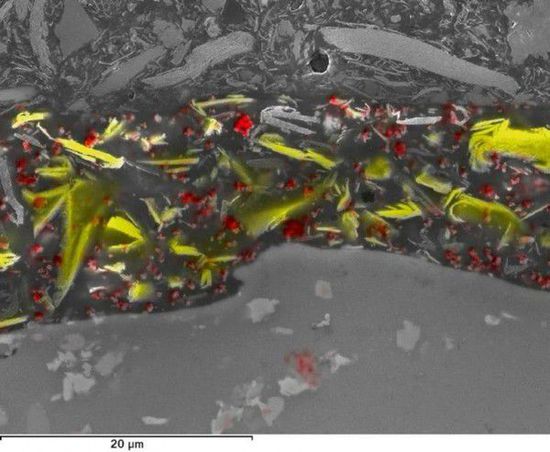

The coating is made of metal-reinforced epoxy resin and solid lubricant, which can be used on the piston skirt surface with a thickness of only 15 microns. Now that validation testing is nearing completion, it is expected to enter the market next year.

EcoTouch-D is a coating developed for aluminum and steel pistons for passenger cars and heavy duty commercial vehicles. Federal-Mogul said that because of the structural rigidity and lubricity of both engines, the formulation of the coating needs more improvement than the EcoTouch. It is reported, EcoTouch-D by the short carbon fiber embedding graphite, it can reduce the piston friction loss of 35%, wear resistance increased by 30%.